The Largest Natural Latex Bedding Manufacturer in Malaysia

honored by

Submit your enquiry below and our representative will be in touch soon.

Why Choose Napure Latex

100% Natural & Pure

No synthetic rubber or fillers

No aniline added

Natural Aeration

Ultra micro-cellular open cell structure promotes natural breathing and air circulation

Environmentally Friendly

Rubber trees have the highest carbon dioxide absorption capacity

Zero harmful by-products compared to synthetic ruber (CO2 and CHx)

Hypoallergenic

Latex naturally has anti-fungus, anti-bacteria, and anti-mite properties

Low Protein Content

Napure’s advanced technology eliminates natural proteins that can cause sensitivity

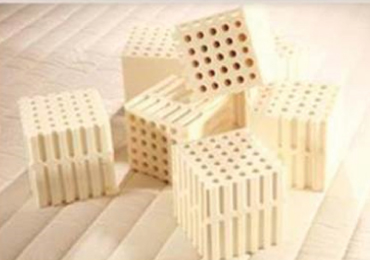

Joint-Free Moulding

Latex blocks manufactured from a single moulding operation up to the revolutionary size of 2m x 2m x 15cm

Multi-Zone Operations

Monozone, 5-Zone and 7-Zone blocks available to give better point-to-point support and spinal alignment

9 Firmness Levels

9 options for levels of firmness to suit every individual’s needs and preferences

International Recognition

Napure’s Latex is used in products worldwide, including Japan, Korea, Europe, Australia, New Zealand, Singapore, Belgium, Canada, Thailand, Taiwan, Indonesia, USA, and more

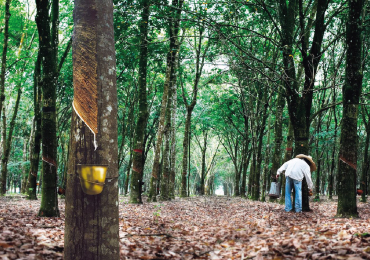

How It’s Made

Napure Latex is made of 100% organic hevea natural rubber

Step 1

Rubber tappers strip a thin layers of bark off the tree to release the latex

Step 2

This latex seeps down the tree and is collected in a cup over the next 6 hours

Step 3

The raw latex sap is then processed into a variety of products, from rubber tyres to latex mattresses

Step 4

Napure moulds the latex into mono-blocks in a single operation without joints, up to 2m x 2m x 1.5m

Step 5

We engineer multiple variations in Zones and Firmness levels to ensure an optimal comfort level for each individual’s needs

Our Certifications

Napure Latex Mattress Components Supply & Export

Submit your enquiry below and our representative will be in touch soon